Hebei Hankai hydraulic cylinder repair seals

20x30x7 oil seal. Firstly, the shaft and housing must be thoroughly cleaned to remove any dirt or debris that could interfere with the seal. The oil seal is then carefully placed over the shaft and pressed into the housing using a seal driver or a soft mallet to ensure a secure fit.

2. Enhanced Performance Properly sealed cylinders allow for smooth operation, enabling the machinery to perform at its best. When seals are worn or damaged, the hydraulic pressure may drop, causing slow response times or erratic movement. This inconsistency can impede productivity and create safety hazards in high-stakes industrial environments.

cylinder seal kits

It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages

It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages It can be used for personal identification, as a signature on official documents, or even as an artistic embellishment on letters and packages 35 52 8 seal. Its versatility makes it a popular choice among artists, writers, and professionals alike.

35 52 8 seal. Its versatility makes it a popular choice among artists, writers, and professionals alike. combi oil seal. In automotive engines, they ensure that engine oil stays within the system, preventing oil loss and maintaining optimal lubrication. In industrial machinery, they protect bearings and other critical components from contamination and wear, prolonging the lifespan of the equipment.

combi oil seal. In automotive engines, they ensure that engine oil stays within the system, preventing oil loss and maintaining optimal lubrication. In industrial machinery, they protect bearings and other critical components from contamination and wear, prolonging the lifespan of the equipment.Metal oil seals are available in a variety of designs and configurations to suit different applications

. Some seals are designed to withstand higher temperatures and pressures, while others are specifically engineered for use in specific types of machinery or equipment. This versatility makes metal oil seals a versatile and reliable solution for a wide range of sealing requirements. In automotive industries, wiper seals are essential for ensuring smooth operation of steering and suspension systems, preventing premature wear due to road debris In automotive industries, wiper seals are essential for ensuring smooth operation of steering and suspension systems, preventing premature wear due to road debris

In automotive industries, wiper seals are essential for ensuring smooth operation of steering and suspension systems, preventing premature wear due to road debris In automotive industries, wiper seals are essential for ensuring smooth operation of steering and suspension systems, preventing premature wear due to road debris dust wiper seal.

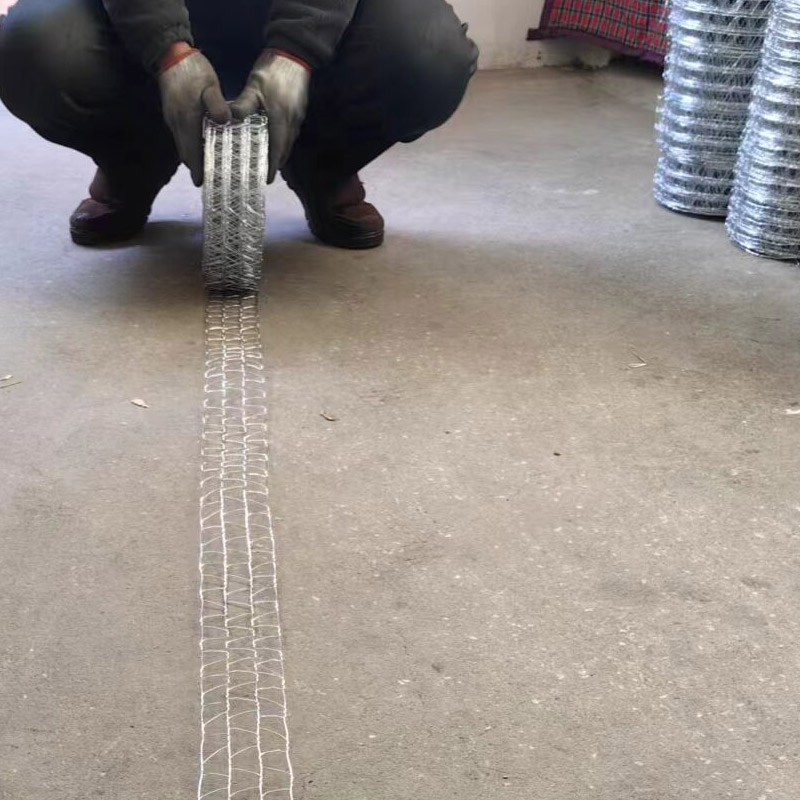

dust wiper seal.There are various types of masonry ties, including continuous ties, strap ties, and anchor ties, each designed for specific applications based on the materials and construction methods used

. Continuous ties are typically used in reinforced walls, providing continuous support along the length of the wall. Strap ties, on the other hand, are often used in situations where a more flexible connection is needed, allowing for movement and shifting without compromising the integrity of the structure. Anchor ties are essential in attaching the masonry to foundation elements, ensuring a solid bond that can withstand environmental stresses.masonry ties

Industrial machinery often incorporates compression springs to maintain force and tension in belts, chains, and other moving parts, ensuring the smooth operation of the equipment. They are also integral to valves and pumps, where they help regulate flow and pressure. In aerospace applications, compression springs must meet stringent standards for reliability and performance, as they are used in critical components such as landing gear, control systems, and actuators.